Keeping in mind pharma industry standards, i2e stepped in as a specialty PPM consultant firm to evaluate gaps and develop an expert-led, stakeholder-informed roadmap for an overall move to a modern, integrated PPM setup.

Methodology followed

As a mid-sized pharmaceutical company expanding rapidly worldwide, the existing PPM tools and processes couldn’t keep pace. The organization had implemented Planisware to support the PMO, but as the company grew and the PMO's scope evolved, the system’s initial configuration became outdated and ineffective. Operations relied heavily on manual coordination and short-term fixes, lacking scalability and coherence.

Key processes like cost estimation, forecasting, and resource planning were siloed, limiting visibility and hindering scenario modeling. Effort and cost data were misaligned—particularly for contractors—making forecasts unreliable. The system couldn’t accurately capture true costs, as contractor work was tracked by fixed rates rather than actual time or FTEs.

To address this, the company sought a life sciences PPM expert to assess current gaps, benchmark best practices, and define a future roadmap aligned with strategic goals.

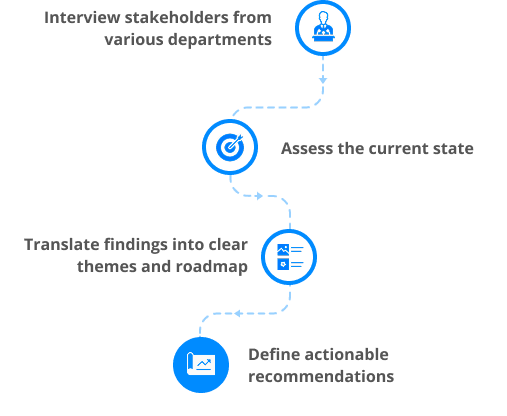

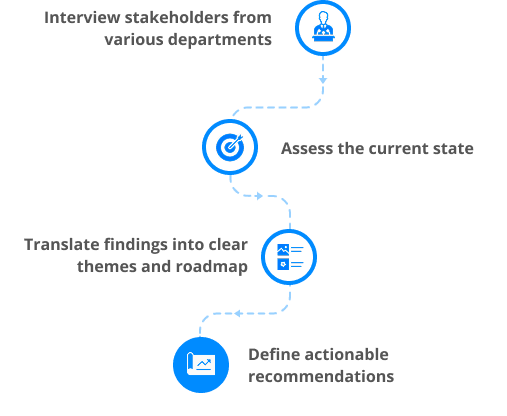

Keeping in mind pharma industry standards, i2e stepped in as a specialty PPM consultant firm to evaluate gaps and develop an expert-led, stakeholder-informed roadmap for an overall move to a modern, integrated PPM setup.

Methodology followed

1. Data and technology infrastructure

2. Reporting and analytics

3. Portfolio and resource management

4. Change management and adoption

5. Execution strategy